Industrial Ball Valve

Description

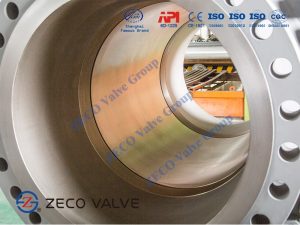

Industrial Ball Valve

Description of Industrial Ball Valve:

ZECO industrial ball valve is widely used in petrochemical, refining, metallurgy, offshore platform and other industries. Our customers include China National Natural Gas Corporation, Chemical Equipment Corporation, CNOOC and other fixed-point supply member units. ZECO industrial valve company carries out strict inspection on each industrial ball valve, and the inspectors are highly responsible for every component, together with the most advanced testing equipment and strict quality management system, so that each ball valve can stand the customers’ careful selection. Among those industrial ball valve manufacturers, ZECO company is sure to provide you with the best products.

Features of Industrial Ball Valve:

1. ZECO industrial ball valve has a special fire protection design and two seals, the first is resilient seal and the second is metal seal. In case of fire, the resilient seal structure will be destroyed at first. At this time, the metal seal will be pushed to the ball by the spring and sealed tightly with the ball to reduce medium leakage;

2. ZECO industrial ball valve in order to avoid in the process of switch electrostatic effect and result in inflammable explosive danger happening, in each ball valve body, ball and stem are designed the anti-static device, composed of stainless steel ball and spring, it can quickly will generate static electricity from the sphere of the valve itself lead to the valve body, smooth delivery, and body;

3. ZECO industrial ball valve in order to better make the valve in the pipeline long-term use, easy maintenance, so in the stem and seat design grease hole, so in regular maintenance or long-term use after the micro-leakage need to repair, can be simple operation, through the injection of sealing grease grease grease, ensure the normal use of the ball valve in the pipeline;

4. ZECO industrial ball valve can be coated with an epoxy coating of up to 1500μm in thickness, depending on customer requirements, in order to better protect the valve against corrosion. This process can effectively prevent the ball valve in some corrosive medium conditions by medium erosion.

Material of Industrial Ball Valve:

| No | Part | Material |

| 1 | Body | ASTM A216 WCB |

| 2 | Bonnet | ASTM A216 WCB |

| 3 | Ball | ASTM A182 F304 |

| 4 | Seat | ASTM A182 F304 + PTFE |

| 5 | Stem | ASTM A276 304 |

| 6 | Anti-static Device | SS304 |

| 7 | Gasket | Graphite + SS304 |

| 8 | Bolt | ASTM A193 B7 |

| 9 | Nut | ASTM A194 2H |

| 10 | O-ring | Viton A |

| 11 | Lever | ASTM A216 WCB |