ZECO Valve is a professional butterfly valve manufacturer in China, producing centerline butterfly valves, double offset butterfly valves, and triple butterfly valves.

What is a Butterfly Valve?

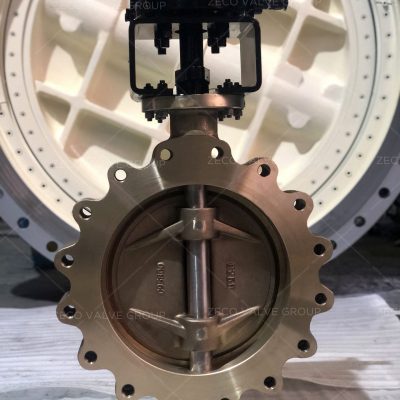

A butterfly valve is a valve used for flow regulation in large pipe diameters in which the disc takes the form of a disk. The operation is similar to that of a ball valve. A plate or disc is positioned in the center of the pipe. The disc has a rod passing through it that is connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

Butterfly Valve For Sale List By Form

According to the structural form, the butterfly valve can be divided into Triple offset butterfly valve, high-performance butterfly valve, metal seated butterfly valve, and double offset butterfly valve. The structural difference of a butterfly mainly lies in whether the stem axis, disc center, and body center are in the same position or eccentric position.

Butterfly Valve For Sale List By Drive Mode

The drive mode of the butterfly valve can be divided into manual, pneumatic, and electric, gear operated, and motorized. The choice of operation mode also depends on the client’s requirements and the limitation of operating conditions.

Butterfly Valve For Sale List By Material

The temperature, pressure, and type of medium affect the valve body and interior material of the butterfly valve. Body materials of ZECO butterfly valves include, but are not limited to stainless steel, wcb, carbon steel, forged, and cryogenic.

Butterfly Valve For Sale List By Size

Butterfly valves are usually larger because they are easier to install on larger piping to save space. ZECO international standard valve company manufactures the butterfly valve of smallest 2 inches, 3 inches, 4 inches, 6 inches, 8 inches, 12 inch, and maximum 96 inches.

Applications of Butterfly Valves

Butterfly valves are important to processes and operations in many different industries. This is because of their range in size and their ability to control the flow of liquids, gases, and slurries. Not only can butterfly valves stop or start the flow, but when partially opened, they can also limit or reduce flow as desired.

Customers from many industries purchase butterfly valves, including those in food processing (liquid), waterworks, irrigation, pipe fabrication, industrial manufacturing, heating systems, and chemical transport.

While there are many different possible applications for butterfly valves, some specific uses include vacuuming, petroleum recovery, compressed air services, air, and water cooling, HVAC, slurry services, high-pressure water services, high-temperature water services, steam services, and fire protection.

Butterfly valves have vast usages because of the variety of designs and materials available. From plain water to abrasive liquids or slurries, these can be fitted in any of the pipelines. These are usually employed in

- Slurries or sludges applications

- Vacuum services

- Steam services

- Cooling water, air, or gas application

Choose ZECO as Your Professional Butterfly Valve Manufacturer

Butterfly valve is operated through the 90-degree rotation of the butterfly plate and can be used in the pipeline for regulating and stopping media. The disc of the butterfly valve is perpendicular to the direction of medium flow. The user can adjust the flow of the medium by opening or closing the butterfly plate.

Butterfly valves are widely used in various industrial fields because of their small size, low cost, and convenient installation. Butterfly valves are divided into three categories, the center line butterfly valve because its stem does not deviate from the center and named, With a rubber seat and no stem packing, the seal is achieved by matching butterfly plate and rubber seat, usually for the soft seal structure for low-pressure water treatment industry and Marine water system.

ZECO Valve mainly produces industrial system valves, including high-performance butterfly valves, and is China’s quality butterfly valve manufacturer. Oil companies and industrial companies will install the limited space, most of the size of the shutoff valves are used to clip butterfly valves and flange butterfly valves because of the small size, and ease of install. But although the installation space is very small products, the material requirements on parts are the same strict. The butterfly valve used for industrial is composed of rubber sealing and metal sealing butterfly valve. The most important part of soft sealing butterfly valve is its seat – metal cover. On the market, a lot of manufacturer use normal metal, so the price of butterfly valves drops very low, what disadvantage does normal metal have? First, the normal metal is general metal sealing effect is not particularly good. Under the long-term use condition, the normal metal seal will not naturally crack because of the toughness and integrity of the original, or it will break because of the impact of debris in the pipeline, thus causing the seal failure. Second, because the normal metal has been used for the first time, the condition of the medium cannot be reached even after the metal is added, which will cause secondary damage in use. In addition, ZECO Valve selects copper which can control the quality of the material on the stem sleeve material. Plastic is mostly used in the market. Compared with the wear resistance of stainless steel stem, the wear resistance of plastic and stainless steel is much better. ZECO Valve will pay attention to the product details, and improve our products on the aspects that may cause impacts, to guarantee that customers do not have to worry about the maintenance cost and communication costs in the long-term use.