Butterfly valve has been a classic valve for decades. In the 1950s, butterfly valves were considered standard and widely spread around the world. ZECO VALVE is constantly improving and bringing butterfly valve products to market. These products prove that ZECO VALVE has been a leader in butterfly valves.

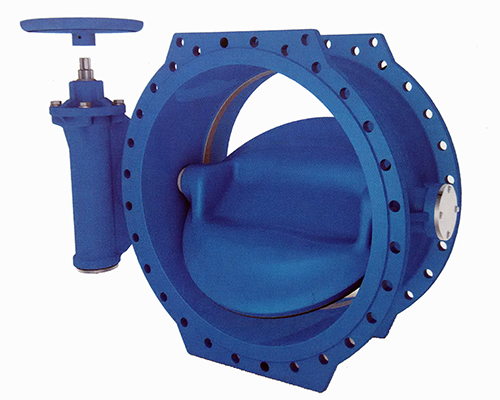

The butterfly valve must be able to withstand huge dynamic pressure when opening and closing, while having sufficient stability. When the valve is fully open, ensure that the valve plate has minimal impact on the flow. The requirements for valve plate thickness at these two points are exactly the opposite. In order to meet these two needs, ZECO VALVE has introduced the latest product, the wave type butterfly valve. The wavy design of the valve plate became the name of this product. On the one hand, the wavy design provides higher stability; on the other hand, pressure loss can be minimized. Water pumps with wave-shaped butterfly valves can reduce the pump lift requirements, which can permanently reduce operating costs. At the same time, the design can effectively prevent cavitation, and has higher value in safety, economic efficiency and durability.

In order for the driving torque to be safely transmitted to the valve plate, a sturdy connection is required. The wave type butterfly valve adopts a multi-shaft connection to ensure torque and zero clearance. Due to the use of a valve shaft structure without a keyway, the polygon shaft can transmit more than 20% of the torque capacity than a valve shaft of the same diameter; at the same time, no drilling is required on the valve plate of this structure, which avoids contact between the valve stem and the medium. The encapsulated bearing is safely isolated from the medium under the protection of the O-ring to achieve an effective seal.

The gear box equipped with the butterfly valve is a slider type gear box. The running torque of this gear box perfectly matches the torque curve of the butterfly valve. The operating torque of the butterfly valve plate varies. As the valve plate approaches closing, the valve torque increases disproportionately. The output torque of the slider type gearbox has the same characteristics. When the valve needs a large torque, the output torque also increases, and the closing speed is also slowed down. This can minimize the danger of water hammer, and can also improve safety and service life of factory equipment.

Overview of double offset butterfly valve

Specification range: its caliber is DN150 ~ DN1600, and its pressure is PN10 ~ PN40;

Main material: its valve body and valve plate are ductile iron, valve stem material is stainless steel, and valve seat material is alloy stainless steel;

Application: It is used for drinking water, non-potable water, and also for sewage, gas and suspension;

Typical application: It is used for water extraction, water production and distribution, water conveyance, sewage treatment and gas supply. It can also be used in industrial water treatment systems.

Features of Double Offset Butterfly Valve

- 1. streamlined valve plate optimizes fluid characteristics, any size valve can maintain stability and high economic efficiency at any time.

- 2. The operation of the slide gear box is consistent with the valve torque curve, which can effectively reduce water hammer during the valve closing process.

- 3. The valve plate and valve shaft are connected by a special polygon shaft, which is stable and does not shake during operation.

- 4. High-quality EKB or enamel protective coating can provide long-term protection for any use conditions.

- 5. Reliable and easy repair kit can provide safe operation and low maintenance cost.