What is a Pneumatic Ball Valve?

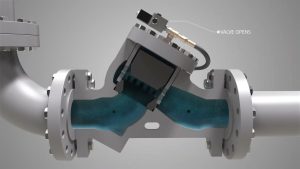

Pneumatic ball valves are used to control the flow of a media, liquid, or gas, by means of a rotating ball with a bore. The rotating ball is controlled by a pneumatic actuator that is capable of turning it.

How do Pneumatic Ball Valves work?

The most common mechanism for a pneumatic actuator for ball valves is the rack and pinion mechanism. This comprises the rack (a linear gear) and the pinion (a circular gear). The rack is attached to a piston which is pushed by compressed air to achieve linear motion. This linear motion is converted to circular motion by the pinion. The pinion drives the stem of a ball valve to open and close positions.

To control the pneumatic actuator for ball valves, the compressed air is regulated by solenoid valves. Electrical signals from the controller energize the solenoid valve to either open or close positions allowing compressed air to flow through to both piston sides of the pneumatic actuator. The piston pushes the rack which turns the pinion connected to the stem of the ball valve.

Types of Pneumatic Ball Valve

Select and buy a pneumatic ball valve online for your application. Pneumatic ball valves are used to control the flow of a media, liquid, or gas, by means of a rotating ball with a bore. The rotating ball is controlled by a pneumatic actuator that is capable of turning it. A ball valve is one of the most common valves due to its simple operation, reliability, long service life, and wide range of application uses.

- 2-way pneumatic ball valves have 2 ports, an inlet, and an outlet. The media flows from one direction to the other and the valve is used to open or close the flow. A 2-way ball valve is commonly called a shut-off valve.

- 3-way pneumatic ball valves have 3 ports. The bore in the ball is not straight, but rather in an L or T formation. This allows for various circuit functions (flow directions) for the valve. It can be used to distribute, mix, or divert flow in the desired direction. Therefore, any of the 3 ports can be an inlet or an outlet.

- Pneumatic ball valve accessories include ball valves with an ISO-top (suitable for a pneumatic actuator).

How to Install Pneumatic Ball Valve?

How is the pneumatic ball valve installed? Can the pneumatic ball valve be installed vertically?

Vertical installation of pneumatic ball valves is possible. Generally, installation on the pipeline can be divided into parallel installation and vertical installation, which is based on the actual situation of customers. But we recommend that it is generally best to install in parallel so that it can be easily maintained and it is very beautiful. But in many special cases, pneumatic ball valves can also be installed vertically. Customers said that if the pipeline space of the parallel installation is not enough, then it will be installed vertically, which will not affect the service life.

Sealing position of Pneumatic Ball Valve

Pneumatic ball valve seal generally consists of four seals: 1. Stem seal ring 2. Midway seal ring 3. Two seals on both sides. The stem seal ring refers to the seal ring where the valve stem operates, generally with tetrafluoro (PDFE) and flexible graphite; the middle seal ring refers to the middle connection valve body seal, generally with tetrafluoro (PDFE) and graphite metal composite gasket; the two sides of the seal ring are: the ball core on both sides of the import and export seal ring. It is generally sealed with tetrafluoro (PDFE) and PPL (high-temperature resistant sealing ring).

Pneumatic Ball Valve Actuator

The pneumatic ball valve consists of two main parts: actuator and valve. The actuator has two kinds: single-acting and double-acting.

So how to make your pneumatic ball valve easy to use and has a long life? The service life of pneumatic ball valves is determined by the on-site use of customers.

To prolong the service life of pneumatic ball valves, the first thing is to keep the gas source stable. The stable gas source can directly affect the speed of the valve switch and the life of the valve sealing ring. It is better to install a couplet on each actuator. This couplet can not only provide stable air pressure but also regularly refuel the cylinder. It can also discharge moisture from the air, which greatly improves the life of the cylinder. The life of the valve is determined by the medium used in the field.

Professional pneumatic actuator ball valve manufacturers and high-quality ball valves will make its life longer. Among various pneumatic ball valve manufacturers, ZECO Valve is the best choice for you. ZECO Valve provides you with high-quality pneumatic ball valve products.